ISO 8735 – 10×26 – A-C1: Understanding the Standard and Its Applications

ISO 8735 – 10×26 – A-C1 is a specific standard that holds significant importance in various industries, particularly those involving measurements, engineering, and mechanical systems. The precise definition and application of ISO 8735 – 10×26 – A-C1 might seem complex, but by breaking it down step by step, this article will help you understand its significance, usage, and practical relevance. Whether you’re an engineer, a technician, or someone involved in quality control or compliance, understanding ISO 8735 – 10×26 – A-C1 can improve your efficiency and understanding of standards that are essential for quality assurance.

What is ISO 8735 – 10×26 – A-C1?

To understand ISO 8735 – 10×26 – A-C1, it’s essential first to explore the structure and context of the ISO (International Organization for Standardization) system. ISO standards are a set of globally recognized guidelines and specifications designed to ensure the quality, safety, and efficiency of products, services, and systems.

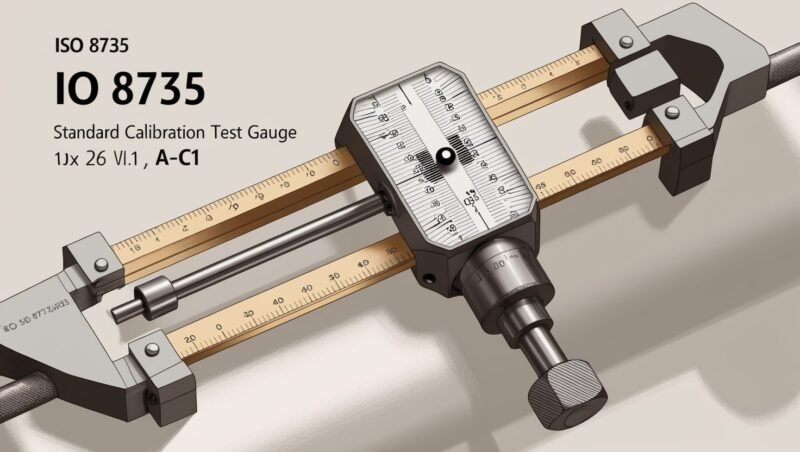

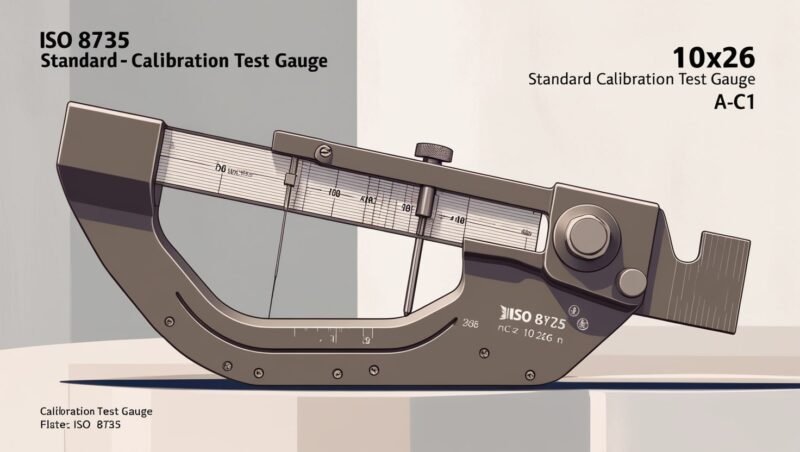

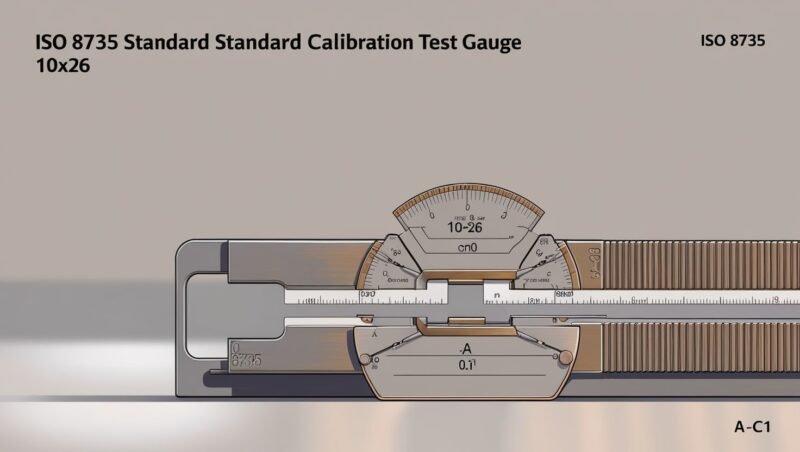

ISO 8735 – 10×26 – A-C1 refers to a specific standard within this system. It applies to the measurement of certain mechanical elements, which include specific tolerances for dimensions and materials. The code “10×26” refers to a particular dimension of a part or component, while “A-C1” signifies a classification or set of attributes related to that component. This precise standard can be found in industries where exact measurement and fitting are paramount.

Understanding ISO 8735 – 10×26 – A-C1 starts with identifying its role in mechanical engineering, manufacturing, and construction. It is part of a broader system of standards designed to guarantee that parts fit together accurately and function as intended, reducing errors and improving overall product performance.

The Structure of ISO 8735 – 10×26 – A-C1

ISO 8735 – 10×26 – A-C1 has a very specific format that includes numeric and alphabetic indicators. The number “10×26” represents specific measurements, likely a ratio or a standard dimension (such as 10mm by 26mm, or some other variation depending on the context). The “A-C1” part denotes a type, class, or tolerance within that measurement standard.

Understanding this specific breakdown is key to fully grasping ISO 8735 – 10×26 – A-C1. Whether you are interpreting it for product design, manufacturing, or quality control, these measurements must be precise, and knowing how they correlate to real-world applications will ensure accuracy in the final product.

In short, ISO 8735 – 10×26 – A-C1 serves as a guideline to ensure that mechanical parts are consistent, reliable, and fit for their intended use. The system helps to manage tolerances and ensure parts are manufactured to precise specifications.

Applications of ISO 8735 – 10×26 – A-C1 in Manufacturing

In manufacturing, using standards like ISO 8735 – 10×26 – A-C1 is crucial for the production of parts and assemblies that must meet strict criteria. For example, if a part is being made for an automotive engine, the parts must fit together seamlessly to ensure safe operation. The tolerances set out by ISO 8735 – 10×26 – A-C1 guide the manufacturer in achieving precise dimensions and shapes that are critical for performance.

Manufacturers rely heavily on these standards to avoid defects and rework, ultimately saving time and money. Parts that adhere to ISO 8735 – 10×26 – A-C1 are more likely to be compatible with other components and systems, reducing assembly issues and minimizing the risk of failure in operational conditions.

In industries like aerospace, automotive, and heavy machinery manufacturing, ISO 8735 – 10×26 – A-C1 helps guarantee the precision and durability of the components that are produced. From design to testing, these exact specifications ensure that every part functions as it should, reducing errors during the production and assembly process.

Quality Control and Compliance with ISO 8735 – 10×26 – A-C1

For companies that produce products using ISO 8735 – 10×26 – A-C1, quality control becomes a significant part of the process. Meeting these standards is not just about ensuring functionality, but also about compliance with international and industry regulations. Having parts that meet ISO 8735 – 10×26 – A-C1 specifications is often required for certification in certain markets, especially where safety and performance are highly regulated.

Quality control checks based on ISO 8735 – 10×26 – A-C1 can include visual inspections, measurements with precision tools, and even computer-aided design (CAD) systems to verify that the parts conform to the required standards. Often, parts must undergo stress testing or be subject to wear and tear conditions to ensure that they will perform consistently over time.

Ensuring that every component is up to standard helps prevent costly mistakes, recalls, or safety issues. For organizations looking to maintain a competitive edge in their respective industries, adhering to ISO standards like ISO 8735 – 10×26 – A-C1 is vital in maintaining a reputation for quality and reliability.

Impact of ISO 8735 – 10×26 – A-C1 on Product Lifecycle

The application of ISO 8735 – 10×26 – A-C1 directly impacts the entire product lifecycle, from initial design and prototyping to final production and maintenance. This standard ensures that components are built to last and function properly, reducing the risk of breakdowns or failures during the product’s operational life.

During the design phase, engineers will reference ISO 8735 – 10×26 – A-C1 to ensure that their designs are feasible and manufacturable within the specified tolerances. This ensures the design is sound before production begins.

As the product moves through manufacturing and assembly, ISO 8735 – 10×26 – A-C1 will guide the production teams to create parts that meet the exact measurements, reducing the likelihood of costly errors or deviations from the design. Once the product is complete, its continued performance is guaranteed by the original compliance with ISO 8735 – 10×26 – A-C1, which acts as a standard for ongoing durability and operational efficiency.

Benefits of Adhering to ISO 8735 – 10×26 – A-C1

The advantages of following ISO 8735 – 10×26 – A-C1 are numerous, especially for organizations that produce parts and products requiring high precision. One of the most important benefits is the assurance of compatibility. Parts that adhere to this ISO standard are more likely to fit and work together without issue, reducing the risk of costly mistakes during assembly.

Another benefit is improved product longevity. When manufacturers follow ISO 8735 – 10×26 – A-C1, they ensure that their components can withstand wear and tear over time, resulting in a longer-lasting and more reliable product. This leads to higher customer satisfaction and a more sustainable business model.

Additionally, ISO 8735 – 10×26 – A-C1 helps streamline production processes. By following a well-defined standard, manufacturers can reduce variability in their products, improve consistency, and ultimately create a more efficient production line.

How ISO 8735 – 10×26 – A-C1 Relates to Other ISO Standards

While ISO 8735 – 10×26 – A-C1 is a crucial standard for certain industries, it is only one piece of the broader ISO standard system. Many industries rely on multiple ISO standards to guide their processes, including those related to environmental impact, safety, and efficiency. For example, ISO 9001, a standard for quality management systems, often works in tandem with ISO 8735 – 10×26 – A-C1 to ensure that quality control processes are in place throughout the production chain.

These standards complement each other, ensuring that products are not only functionally correct but also manufactured in ways that reduce waste, improve worker safety, and create sustainable, high-quality products. Understanding how ISO 8735 – 10×26 – A-C1 fits within the larger framework of ISO standards is essential for companies looking to maintain compliance with international best practices.

Adopting ISO 8735 – 10×26 – A-C1 in Your Organization

For companies considering adopting ISO 8735 – 10×26 – A-C1, the first step is understanding its requirements in the context of their own processes. You’ll need to assess the materials, measurements, and tolerances currently used in your manufacturing processes and compare them against the specifications laid out in this standard.

Next, invest in proper training for your engineering and production teams. Educating them on ISO 8735 – 10×26 – A-C1 will ensure they understand the importance of following the standard and how it impacts overall product quality. Tools and technologies like CAD systems and automated measurement devices can assist in adhering to these precise requirements.

Once your organization is familiar with ISO 8735 – 10×26 – A-C1, implement it across all relevant production lines and processes. Make sure that every stage, from design through to final testing, adheres to the specifications outlined in the standard.

Challenges in Implementing ISO 8735 – 10×26 – A-C1

While the benefits of ISO 8735 – 10×26 – A-C1 are significant, there can be challenges in adopting it, especially for companies unfamiliar with ISO standards. The most common challenge is ensuring that all parts and components align with the exact tolerances and measurements outlined in the standard.

For some manufacturers, particularly those producing custom parts or working with highly complex designs, meeting the precise requirements of ISO 8735 – 10×26 – A-C1 can require significant investment in training, tools, and equipment. Additionally, ongoing quality control checks and audits are necessary to maintain compliance.

Overcoming these challenges requires a commitment to quality and a strategic approach to integrating ISO standards into every aspect of the manufacturing process.

Conclusion

In conclusion, ISO 8735 – 10×26 – A-C1 plays a pivotal role in ensuring the quality and precision of mechanical parts across a variety of industries. By adhering to this standard, manufacturers can guarantee that their products meet stringent tolerances, resulting in higher efficiency, improved product longevity, and reduced operational risks.

For those in the manufacturing, engineering, and quality control sectors, understanding ISO 8735 – 10×26 – A-C1 is essential. It ensures that parts fit together as intended and that the final product functions smoothly and reliably. Whether you are involved in the design, manufacturing, or quality testing of components, following ISO 8735 – 10×26 – A-C1 will lead to better products, smoother operations, and greater customer satisfaction.